China's future wood floor industry will develop along the following directions:

1. To scale, standardization, science and technology, environmental protection, service direction development.

2. Through scientific and technological means gradually improve the use of wood floor function, improve the dimensional stability of wood floor, make wood more wear-resistant, beautiful, fire prevention, water resistance, antistatic, etc.

3. The surface finishing of Solid Wood Floor can take various forms, such as the use of high wear-resistant surface paint or the use of wear-resistant transparent materials for cladding.

4. Composite wood floor( Laminate wood floor and Solid wood Composite floor) will become the trend of wood floor industry development, composite wood floor in the future mainly includes the composite of wood and other materials, the composite of high-quality broadleaf wood and fast-growing wood, the waste material and small wood of high-quality hardwood are processed into specification materials and composite into floor, the composite of high-quality floor, and the composite of high-quality wood and wood-based panel. composite wood floor not only can effectively save wood resources, but also has environmental advantages. It is believed that with the further development of the world environmental trend, composite wood floor will also get faster development.

status of industry:

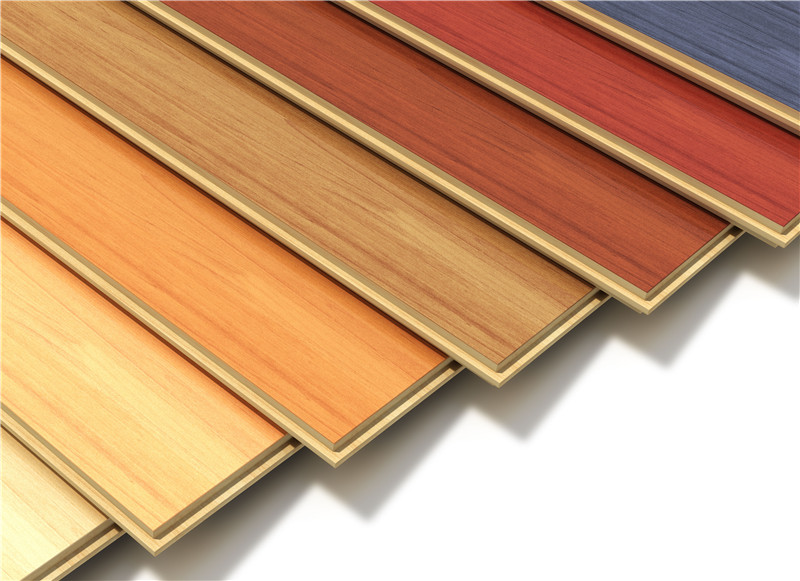

Wood flooring produced in China is mainly divided into Solid Wood Floor, Laminate wood floor, Solid wood Composite floor, Multi-layer Composite floor and Bamboo Floor and Cork floor have six major classes.

1. Solid Wood Floor mainly includes Mortise Join Flooring (also known as Grooved and Tongued Floor), Flate Join Flooring (also known as The Flat Floor), Mosaic Floor, Finger joint floor, Vertical Wood floor and Laminated floor, etc. The scale of Solid Wood Floor production enterprises is uneven, most of them are small, backward equipment, and the overall level of technical equipment is low. Among the more than 5,000 production enterprises, only 3%-5% of them have a output of more than 50,000 square meters. Most of these large and medium-sized enterprises imported equipment from abroad. Its production and sales spin accounted for about 40% of the whole market; However, most small enterprises are difficult to control the tree species, material selection, material quality and processing technology due to the low quality of personnel, technical equipment and management level, and there is a certain waste of resources.

2. Laminate wood floor can be generally divided into two categories: the strong test wood floor based on medium and high density fibreboard and the Laminate wood floor based on particleboard.

3. Solid wood Composite floor can be generally divided into three categories: three-storey Solid wood Composite floor, multi-storey Solid wood Composite floor and joinery Composite floor.

4. Bamboo Floor can be generally divided into Bamboo Floor and Bamboo composite Floor two categories.

5. What we usually call a multi-layer Composite floor is actually a multi-layer Solid wood Composite floor. In the latest national standards, it is called impregnated paper laminate veneer multi-layer Solid wood Composite floor, which is explained as follows: impregnated paper laminate veneer multi-layer Solid wood Composite floor, impregnated paper laminate as the veneer layer, plywood as the base material, The tongue-edge floor that classics pressure amalgamate processing makes. With the wear resistance of laminate floor and the deformation resistance of Solid wood Composite floor, it has performed well in three harsh environments (public places, geothermal and humid) through practice.

6. Because the cork floor of China suffers the limitation of resource, production company quantity is less consequently.

7. The floor industry in the Pearl River Delta region has begun to rise, including more and more floor brands in Guangdong and Zhejiang. Raw materials in coastal areas are mainly imported from Indonesia, Myanmar, Europe and the United States, which is commonly known as imported materials.

8. At present, the brand concept of the domestic flooring industry has been gradually deeply rooted in the people's hearts, and the North-South pattern has been gradually realized. The promotion of brand awareness has a positive effect on the whole flooring industry, which represents that China's flooring industry has gradually become mature and stable.

Post time: Aug-19-2022