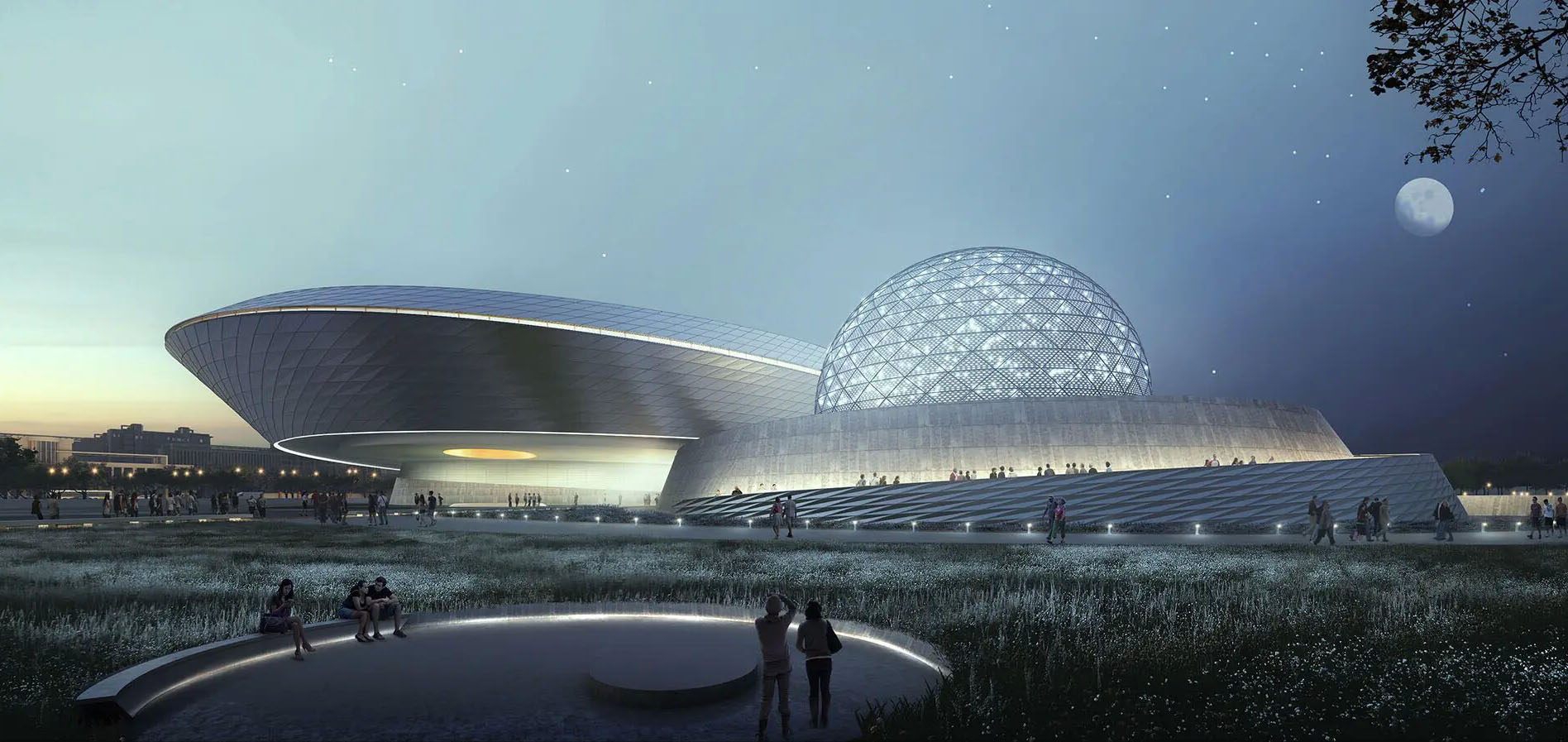

As a curtain wall material with nearly 70 years of successful application experience abroad, anodized aluminum panel has also begun to shine in domestic construction projects in recent years, among which the most popular are Shanghai Planetarium and TAG Art Museum. Anodized aluminum panels are used throughout the facade of the Shanghai Planetarium, and diamond-shaped cutting panels are used at different angles.

With the sunrise and sunset of the night light show, the viewer can see different light and shadow effects from every Angle.

And Jean Nouvel's new work, TAG Art Museum. The gallery's gallery is decorated with 127 pieces of anodized aluminum electric sunshade fans, which give the building's facade a metallic sheen under the sunlight.

In addition, in recent years in the domestic application of anodized aluminum panel projects are also many, such as: Large landmark buildings: Wuyuanhe Culture and Sports Center, Henan Science and Technology Museum, Jiaxing Station, Linping Sports Park Tennis Hall, Haixin Bridge, JW Marriott Marquis Hotel, etc.

So what is the difference between anodized aluminum panel and fluorocarbon aluminum panel commonly used in the industry? This article is explained through four aspects: surface treatment process, surface hardness, easy cleaning, and durability.

01.

Surface treatment technology

Anodized aluminum panel

First of all, what is the anodizing process? Anodizing is an electrochemical process that forms a dense oxide layer on aluminum.

Al2O3 is a chemical structure that never converts, has the highest hardness among oxides, and is also extremely weather-resistant. Even if the oxide layer encounters the fire, the aluminum melts but the oxide layer will not change. It is not an exaggeration to say that anodized alumina is the Rolls Royce of aluminum panel. In fact, it is not an exaggeration to ask what surface treatment method can achieve such dense characteristics?

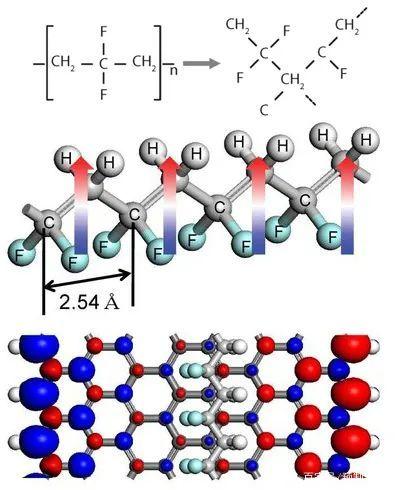

Fluorine carbon aluminum panel

Fluorocarbon aluminum panel is sprayed on the aluminum surface by the paint treatment process. Although fluorocarbon coating is added with fluorine resin to improve the performance, the polymer structure of the paint film will still be irradiated by ultraviolet light cracking, pulverizing and peeling.

02.

The surface hardness

The surface hardness of aluminum oxide panel and painted aluminum panel is tested by the commonly used pencil hardness test. We can find that the hardness of the pencil is 9H (the highest hardness pencil in the laboratory), also can not scratch the oxide film, that is, the hardness of the oxide film is more than 9H.

If the hardness of oxide film is measured by Mohs hardness, the familiar diamond has a Mohs hardness of 10, while the components of oxide layer, aluminum oxide and sapphire, have a Mohs hardness of 9 after diamond.

03.

Easy to clean

A lot of fluorocarbon aluminum curtain wall, installed only about 3 months will appear infiltration and vertical flow pollution phenomenon, fluorocarbon aluminum plate after a large amount of dust adsorption, with the extension of time, the accumulation of pollutants increasingly serious and migrate along the porous surface to the coating interior, seriously affecting the appearance of the curtain wall.

When examined under a microscope, the fluorocarbon paint film can be seen at a magnification of 500 times, resembling a porous spongy structure.

Due to the high density of the anodized aluminum panel, the structure could not be seen in the 500x magnification, so it had to be magnified to 150,000x. The result was amazing. The oxide film is like a tight structure without any gap of the fortress, firmly long on the surface of the aluminum substrate, aluminum panel to the highest level of treatment must be No.1!

The oxide layer of anodized aluminum panel is similar to corundum ceramic layer, the surface does not take charge and does not absorb dust. The extremely dense structure makes it impossible for pollutants to penetrate, and pollutants floating on the surface will be washed away by rain. As long as conventional cleaning, the wall can be as new for years.

Fluorine carbon aluminum panel to the surface of the fluorocarbon polymer resin coating (understandable for plastic), take charge adsorption dirt easily, and in the light will gradually roughen, intensifying the dirt, hang leave dirt into porous film, forming a vertical flow pollution after the rains washed out, even with a strong chemical detergent temporarily alleviate smudgy degree, will also lead to curtain wall is more and more old.

04.

The durability

According to the above analysis, due to different surface treatment methods, there is an inner layer space in the fluorocarbon paint film that is easy to be corroded. After filamentous corrosion, the surface is prone to peeling, foaming, cracking or fragmentation. After weathering, the surface of the paint film will powder to form fine powder, and the gloss and color are significantly reduced, leading to the deterioration of the surface appearance.

In contrast, the anodized aluminum panel, after nearly 70 years of experience at home and abroad, as long as the normal cleaning and maintenance, the house can endure.

Founded in 1883, PPG Industries, the world's leading exterior paint giant, has used anodized aluminum for its own administrative headquarters and research and development center, which was built 34 years ago without routine maintenance.

In the PONT DE SVRES office project, the anodized aluminium curtain wall is much older, 46 years old, and has not undergone routine maintenance.

Anodized aluminum sheet with excellent weather resistance, can adapt to all kinds of environment.

Post time: Aug-17-2022