Product Center

High Performance Aluminium Wooden Sheet - FR A2 ALUMINUM COMPOSITE PANEL PRODUCTION LINE – BOTEC

High Performance Aluminium Wooden Sheet - FR A2 ALUMINUM COMPOSITE PANEL PRODUCTION LINE – BOTEC Detail:

Product Description

1. Non-combustible inorganic core material + metal material is the perfect combination of strength, flexibility, fire resistance, moisture resistance, heat insulation, sound insulation and decoration.

2. Excellent fire performance. In the combustion test, zero fire spread, no halogen, no smoke, no toxicity, no dripping, no radiation, etc. have proved its excellent safety performance, and it has the characteristics of green environmental protection.

3. Excellent decorative performance, elegant and beautiful products, corrosion resistance, pollution resistance, enduring.

4. The perfect combination of strength and flexibility completely makes up for the lack of strength of the aluminum composite panel. It can be made of hyperbolic shape, easy to install and maintain.

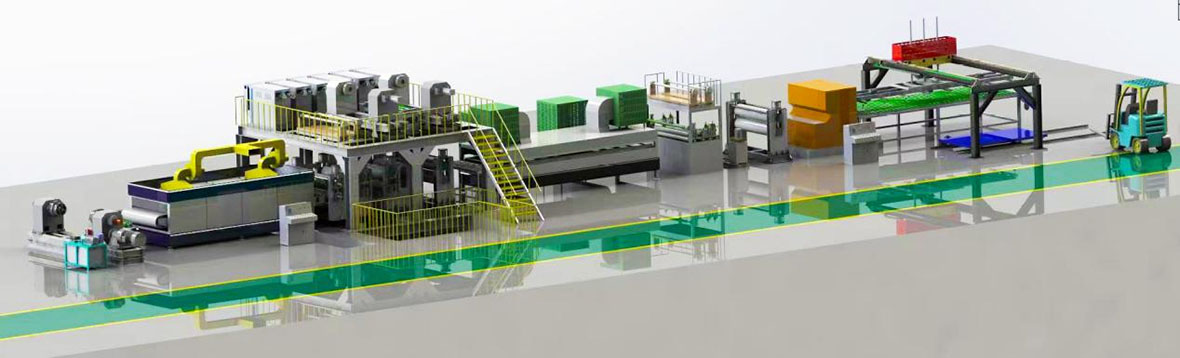

Production Principle

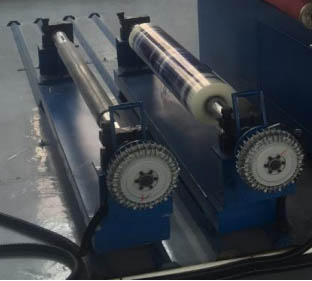

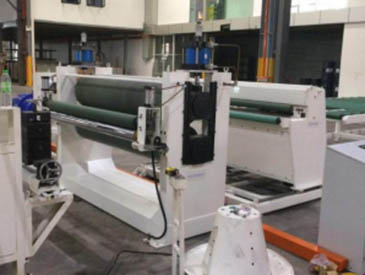

The coiled A2 core material is released through the unwinder, and then the core material is heated at high temperature in the oven to soften the core coil. At this time, the core coil has plasticity. After the core material passes through the oven, the upper and lower aluminum The skin is released by the aluminum coil unwinding machine, the adhesive film is passed through the pre-composite roller, and the adhesive film is attached to the aluminum skin, and then the upper and lower aluminum skins pass through the compounding unit to make the aluminum skin and the core panel fit together. The temperature of the machine can be set separately. After passing through several groups of compound units, after high-temperature hot lamination and extrusion, the panel is pasted and formed, and then cooled by a water-cooled air box, and then passed through a leveling roller to stick the adhesive film firmly. At this time The board is then trimmed. After the width is determined, the board passes through the driving drum and then arrives at the shearing machine. The shearing unit cuts the fixed length according to the set length. After the composite board is generated, the board is transferred to the pallet through the automatic loading and unloading platform. Stacked, and finally manually packaged and shipped.

Product detail pictures:

Related Product Guide:

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for High Performance Aluminium Wooden Sheet - FR A2 ALUMINUM COMPOSITE PANEL PRODUCTION LINE – BOTEC , The product will supply to all over the world, such as: Palestine, Eindhoven, Algeria, With a wide range, good quality, reasonable prices and stylish designs, our solutions are extensively used in beauty and other industries. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.