Product Center

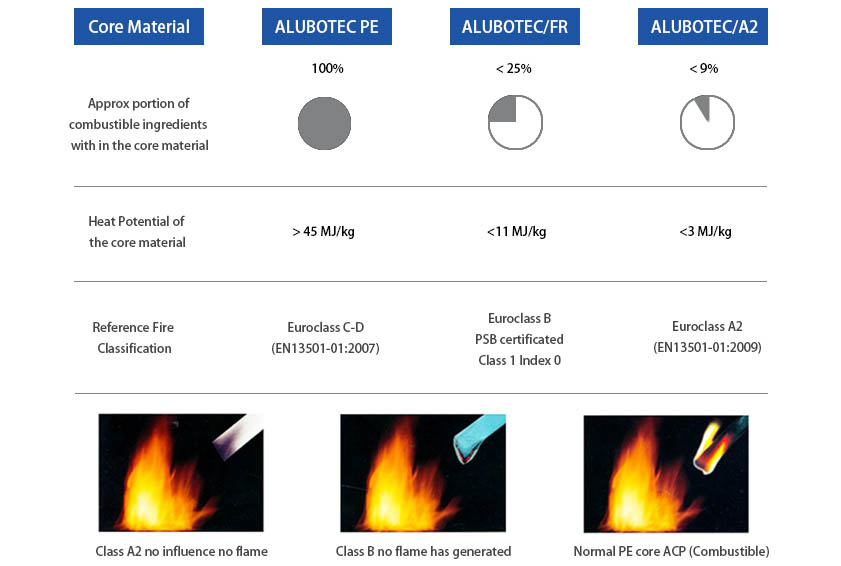

FR A2 CORE COIL for PANELS

Product Description

ALUBOTEC is in the upstream position in the industrial chain and has a large initiative. At present, the product technology is in the leading position in China. The products are not only sold to several domestic provinces and cities, but also exported to more than 10 other countries and regions in the world. Compared with the main domestic and foreign competitors: so far, few domestic companies have developed production equipment that can produce A2 grade fireproof core rolls, so there is not much domestic competition. The A2 grade fireproof core roll developed by our company can gradually occupy the domestic market and enter the international market with the advantages of excellent quality and low price.

The technological innovation of the product lies in

① The use of domestic original non-movement material ratio process, easy to obtain raw materials, low cost, waste environmental protection, green pollution-free.

② Environmental protection, non-toxic, harmless, high viscosity, high durability, Vinyl acetate Aopolymer is used as binder. Based on the performance of the original core board, the flexible and flexible a-grade fire core roller is achieved, and the smooth realization of winding is guaranteed.

③ The first "alternate, piecewide drying, extrusion integration" process, to ensure product strength, compactness, flatness, at the same time to achieve continuous, streamlined winding operation.

Specification

The production specifications are generally 800-1600mm, and the thickness is generally 2-5mm.