Product Center

Factory wholesale Aluminium Composite Cladding System - AUTOMATIC FR A2 CORE PRODUCTION LINE – BOTEC

Factory wholesale Aluminium Composite Cladding System - AUTOMATIC FR A2 CORE PRODUCTION LINE – BOTEC Detail:

Machine Main Technical Data

1. Raw material

Environment protection FR non-organic powder&Special water miscible liquid Glue&Water: Mg(oh)2/Caco3/SiO2 and other non-organic powder ingredients as well as Special water miscible liquid glue and some percentage of water for the formula details.

Non-woven fabrics film: Width: 830~1,750mm

Thickness: 0.03~0.05mm

Coil weight: 40~60kg/coil

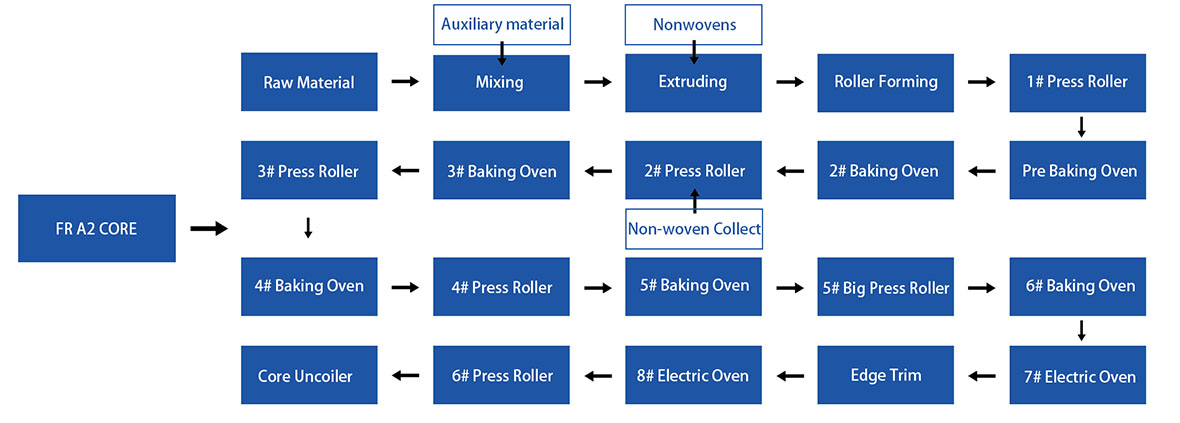

Remark: Firstly start with 4layers of non woven fabrics film and top for 2layers and bottom for 2layers, and 2layers of them will be recoiled after conveying the core to the oven and finally the remaining 2layers will stick to the core after melting.

2. Finished composite panel

Width: 800-1600mm.

Thickness: 2.0~5.0mm.

Production speed: 1200~2000mm/min(Normally for 1800mm/min).

Calculation based on: width of 1240mm*(3~4mm) (adjust as per product’s thickness); raw material/formula/production technique/operation skill can effect the production speed.

3. Production line cooling water requirement (recycling)

Q= 0.5-1.5M3/H; P=Normally for 0.7KG/CM2, (design for 0.5~2kg/cm2 ).

Input temp T1: ≤20℃, ≥0.3Mpa, hardness: 5-8odH.

Mainly used for powder mixing and combination of the formula and water AC cooling recycling and machine front parts-cleaning and other small quantity of recoiler magnetic brake application.

4. Total energy consumption: (230/400V)/3 phase/50HZ.

Power Supply: Installed capacity for FRA2 class: 240kw (actual energy consumption around 145kw).

Electric cabinet working environment: temp & humidity ≤35℃, ≤95%.

Gas supply: Totally for 6ovens and about 110M3/H for the gas requirement(LPG or LNG),averagely for 78M3/H.

5. Total Compress Air volume

Q=0.5~1m3/min P=0.6~0.8Mpa

Air Consumption: Screw Type of Air Compressor with ≥1m3 air storage tank and motor of≥ 11KW

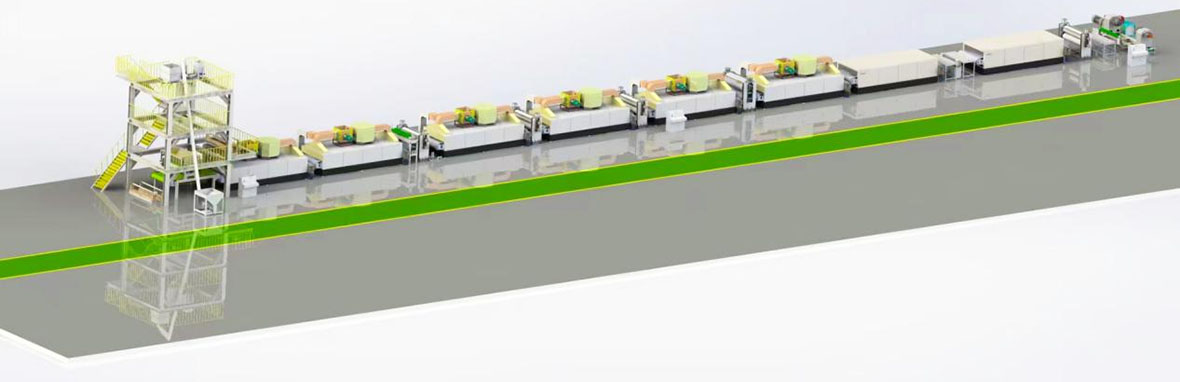

6. Size of the unit

Length* width* height (m): 85m*9m*8.5m(Front platform of the machine for 8.5m )

Total weight (approximately): 90 tons

Factory size (reference)

Length * width (m): 100*16

Crane: lifting capacity 5 tons

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Factory wholesale Aluminium Composite Cladding System - AUTOMATIC FR A2 CORE PRODUCTION LINE – BOTEC , The product will supply to all over the world, such as: Egypt, Estonia, Brazil, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!